What can Food Companies do to Combat Hidden Hunger?

More than two billion people suffer from hidden hunger, making it the most widespread health problem in the world. Hidden hunger is a chronic deficiency of micronutrients, often caused by poor and unvaried diets that lack sufficient minerals and vitamins. It is especially common in low-income countries where food consumption mainly consists of heavily refined wheat, maize and rice. The effects of hidden hunger are devastating not only for the individuals suffering cognitive and physical impediments but also for their societies and economies. Fighting hidden hunger requires cross-disciplinary action that ensures the micronutrients available in soils and crops can be absorbed by the human body.

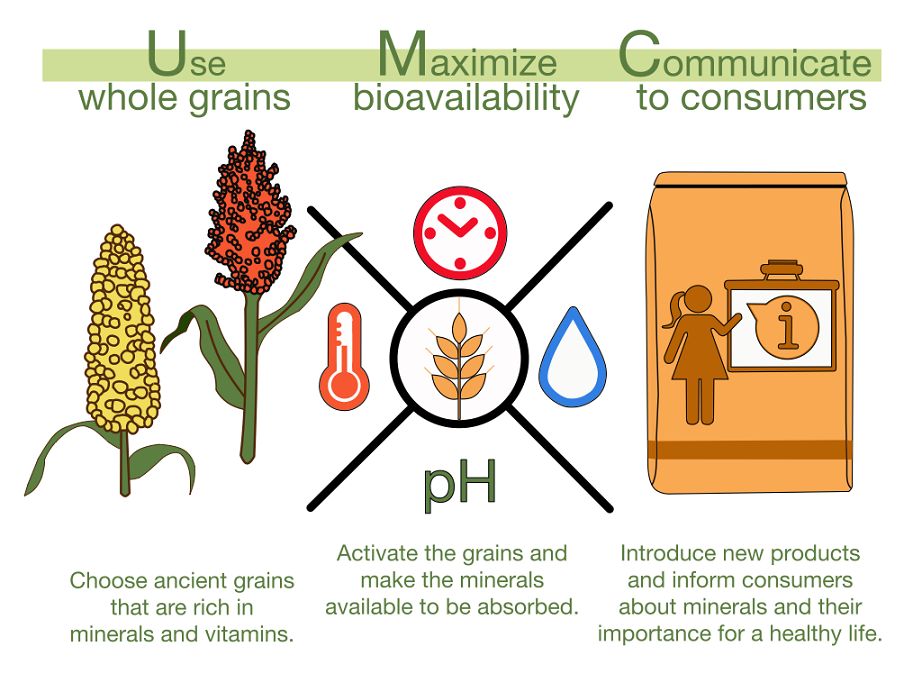

Food processing companies have a unique opportunity to combat hidden hunger through their chosen raw materials and methods used in their production, as well as their link to consumers. Our SIANI Expert Group, composed of Inclusive Business Sweden, Hidden in Grains and BioInnovate Africa, has identified three actions that processing companies can take to tackle hidden hunger.

1. Use micronutrient-dense whole grains as the primary product

Thousands of grain varieties have been cultivated since wild seeds were first domesticated. During the Green Revolution that started in the 1960s, previously cultivated grain seeds were almost completely replaced by a small number of high yielding varieties of rice and wheat (1). These new varieties became popular due to their high yields and supply of macronutrients in the form of proteins and carbohydrates, rather than their micronutrient content in the form of minerals and vitamins. Today the food industry uses these varieties almost exclusively, which have resulted in a loss of 75% of the world’s traditional grain varieties (2).

Grains are among the most nutrient-dense foods available, but only in their form of whole grains. Maize, rice and wheat provide more than half of all the calories in the world. Unfortunately, the grains consumed today are heavily refined products that have lost most of their minerals and vitamins (see diagram 1). In processed white wheat flour, for example, up to 90% of all micronutrients are lost when modern milling removes the husk, the bran and often the germ as well, leaving only the endosperm material that is the store of energy for a seed to sprout and grow. The subsequent loss of essential micronutrients from many people's diets causes chronic deficiencies of essential minerals and vitamins.

To combat these deficiencies, the hidden hunger, food companies can improve our staple foods by choosing traditional and micronutrient-dense grains as the primary raw material in their products. As shown in diagram 2, traditional grains are richer in minerals than modern varieties. In parts of the world, such as in Eastern Africa, older traditional varieties like sorghum and millet are still in use (3, 4). Many food companies are starting to work directly with farmers’ cooperatives to secure the supply of such traditional grains, in order to bring them back and incorporate them in their production.

2. Increase mineral bioavailability through hydrothermal processing

“All research ever done in this field shows that cereals have never been eaten raw or unprepared. Traditional treatments were very time-consuming and in modern times new techniques have to be developed. This must be done with honour and respect for the complexity of life” – Anni Gamerith, Institute of Technology, Graz, Austria, 1958

Cereals are cultivated grasses that produce grains, nutrition-rich seeds designed by nature to survive until it is time to grow into a new plant and eventually produce new seeds. For this purpose, the vitamins and minerals are held by phytate, a binding chemical compound, to be released only when certain environmental criteria are met. Ruminant animals can access these nutrients in raw grains because their multiple-chambered stomachs produce a phytate-breaking enzyme. But non-ruminants, including humans, cannot gain the vital micronutrients from raw grains. However, cultures around the globe have learned to prepare grains to increase their available nutrients, primarily using fermentation and traditional hydrothermal techniques combining water, heat and sometimes pressure. Such methods break down the phytate and increase the bioavailability of minerals like phosphorus, iron, zinc, copper and magnesium.

By adopting hydrothermal processing of whole grains using simple and inexpensive modern techniques, food companies can create products that reach the iron absorption of red meat and increase zinc absorption by up to 400% (5, 6, 7). As part of the work of our SIANI Expert Group, food companies from Uganda, Kenya, Ethiopia and Tanzania are receiving direct support to improve their processes and the nutritional value of their grain-based food products, using locally grown raw material and improved processing methods. Hidden in Grains is a food company from Sweden focusing on modern hydrothermal processing, a method well suited for industrial use that has been optimized in several research projects during the last decades. (8, 9) In April 2021, an online training on these topics was conducted by Hidden in Grains, Stawi Foods and Fruits, and Inclusive Business Sweden. It is now available for actors all along the value chain of grains in SIANI’s website!

3. Communicate to consumers

What people consume depends on many factors, from preferences shaped by culture or social norms, to what is available and affordable. Victims of hidden hunger may not understand the importance of a balanced and nutritious diet. This is where food company communication channels, together with public institutions, can play a key role. It is vital that food companies’ nutritious products reach the market. It is equally important that consumers understand why they should change their purchasing habits and adopt good food preparation practices. Through marketing campaigns, for example using the packages of their food products as a communication tool, companies can reach out to more consumers and increase their market opportunity. In another blog we talked about some of the arguments and benefits food companies can communicate to consumers, as well as the complex function that regulates the absorption of minerals in the body.

A version of this article was first published by SIANI.

References

- Nelson, A. R. L. E., Ravichandran, K., & Antony, U. (2019). The impact of the Green Revolution on indigenous crops of India. Journal of Ethnic Foods, 6(1), 8.

- FAO Biodiversity for Food and Agriculture, 2019

- Frei, M., & Becker, K. (2004). On rice, biodiversity & nutrients. University of Hohenheim, Stuttgart.

- Pichop, G. N., Abukutsa-Onyango, M., Noorani, A., & Nono-Womdim, R. (2014). Importance of indigenous food crops in tropical Africa: case study. In XXIX International Horticultural Congress on Horticulture: Sustaining Lives, Livelihoods and Landscapes (IHC2014): 1128 (pp. 315-322).

- Sandberg A-S. (2020). Rätt beredning och processen av växtbaserade livsmedel minskar risk för brist på järn och zink. Nutritionsfakta 2020

- Hurrell, R. F., Reddy, M. B., Juillerat, M. A., & Cook, J. D. (2003). Degradation of phytic acid in cereal porridges improves iron absorption by human subjects. The American journal of clinical nutrition, 77(5), (pp.1213-1219).

- Fredlund K. et al. (2003) Hydrothermal treatment and malting of barley improved zinc absorption but not calcium absorption in humans. European Journal of Clinical Nutrition volume 57 (pp.1507–1513)

- E-L. Bergman, K. Fredlund, P. Reinikainen, A-S. Sandberg (2001) Development of predictive models for optimization of phytate degradation in wheat and rye during hydrothermal processing. Cereal Chemistry 78 (2). (pp.144-50).

- Bergman, E. L., Fredlund, K., Reinikainen, P., & Sandberg, A. S. (1999). Hydrothermal Processing of Barley (cv. Blenheim): Optimisation of Phytate Degradation and Increase of Free Myo-inositol. Journal of Cereal Science, 29(3), (pp.261-272).