A call for producing construction materials from agricultural wastes

Protecting forests, promoting biodiversity and value addition to wastes

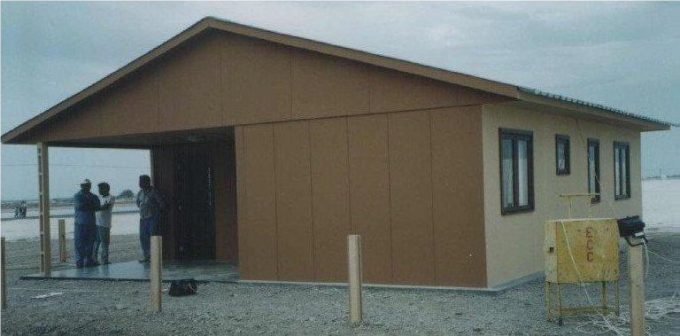

The production of environmentally and easily replicated value added bio-composites from conventional and non-conventional raw materials is aimed at developing a product that can conveniently stand as an alternative for wood products to meet the demand for sustainable construction materials for core and low cost housing in rural and urban areas, furniture, electronics, automobile industries and increase farmers’ income, prosperity, as well as alleviate poverty.

These products are hybrids of organic, inorganic (cement) and plastic (virgin HDPE and recycled LDPE) raw materials reinforced with assorted wood, weeds and agricultural by-products, using adaptable and innovative manufacturing techniques. The cement or plastic matrix serves to bind the assorted wood wastes, weeds and/or agricultural by-products together to produce a durable panel product. The use of Portland cement as binder confers on the product its good reaction to fire behavior, high durability, high stiffness and strength, good sound insulation and excellent dimensional stability relative to other wood-based composites. These products are versatile and affordable because they can be suitably made from a wide range of non-conventional raw materials which are regarded as wastes and sourced locally. Their utilization in building construction reduces the pressure on existing forest resources and increase the income of the community inhabitants.

Justification

If fully implemented, the development of this innovative product will reduce and alleviate poverty through the sales of the products and byproducts/wastes by indigenous people. Furthermore, environmental degradation and pollution arising from burning and other conventional means of waste disposal will be prevented and this will bring about the availability and affordability of the new value added products for construction works sustainably. The products will create job opportunities for the rural inhabitants, produce value added bio-composites as well as protect and conserve forest biodiversity. These products are more resistant to bending force and biodeteriorating agents. Their production will create passion for using new products from bio-wastes and mitigate climate change through the provision of value added panel products capable of serving as alternatives to sawn timber in the building industry. The utilization of these products will develop innovative science and technology in engineering, architectural designs and in building mega structures.

Production Process

To produce this product, raw materials will be processed into flakes using flakers, which is in turn converted to particles by hammermilling. Particles generated will be screened to remove all forms of impurities before board manufacturing. In case of inorganic bonded boards, the particles are treated in hot water to remove the superfluous materials capable of inhibiting the setting and curing of the binder. The particles, binder and additive are mixed together based on experimental design before it is formed inside a mould. Thereafter, the mat formed is prepressed and pressed to attain the target thickness. At the expiration of this procedure, board will be conditioned, cut into specimens and tested for strength and dimensional movement. Data obtained will be analyzed to determine the effect of the variables that formed the board.

Building concepts using cement bonded particle boards from wood particles have been developed by Traulit, Sweden and Eltomation B. V., Holland. Also, the Forestry Research Institute of Nigeria initiated the development and production of cement-bonded particleboard with particles of wood species available in Nigeria in 1979. Since then, not less than seventeen hardwood species have been tested for wood-cement composite manufacture. The boards produced have been used as ceiling boards, wall partitions and furniture components.

However, agricultural wastes and weeds have also been successfully investigated and found suitable for various applications in other to achieve acceleration actions in new and existing businesses. This initiative was borne out of increased depletion of wood resources as raw materials due to over exploitation and the cry for climate change challenges to bring about a new novelty in building and construction businesses.

Conclusion

Cement bonded composites and plastic bonded composites can be manufactured using treated particles from plant dry matters and waste materials. The boards have been found to be dimensionally stable with better strength properties. The product can be commercialized to meet the panel product needs for interior and exterior use in the construction industries worldwide. Suffice to say that investment in this industry has the potential to eradicate poverty, improve socioeconomic standards of people, mitigate climate change by reducing the pressure on the forest resources, as well as revolutionize the orientation in design, technology and industrialization through sourcing, processing, new products development and utilization of raw materials and final products. Promote, support, and collaborate in the execution of common projects, in order to have a prosperous world in perpetuity and sustainably as well as curb environmental pollution and siltation of water ways.

Recommendations

Entrepreneurs should embrace this comprehensive solution for improving the supply of construction materials by making use of all cultivated agriculture byproducts and enormous weeds in the world. The adoption of these value added panel products as material in the building industry will create a new market outfit with growing demands for low cost and core housing delivery in rural and urban areas of the world. The issue of food security, wellness, livelihoods, poverty alleviation, Industrial development and growth will be sustained. Private investors and financial institutions should support the researchers in the universities to explore and provide concerted data of all highly cultivated agriculture produce with the view to assess the byproducts generated as source of raw materials for panel products. Also national and international institutions should support entrepreneurs through the provision of funds for the establishment of the industry.

Entrepreneurs that intend to adopt this solution should: seek to build a stable sustainable economy for the wellness of rural people; develop a mentality of poverty alleviation and prosperity; have a definite goal in view to organize and direct live impacting decision; diversify investment to accomplish intended goals.